AI is not a technology solution, it is a business strategy

The global industry is abuzz with AI and the technological revolution it is likely to bring to the business world and how it is likely to fuel disruptive transformations to the working populace. While this buzz continues to build-up in the real-world, we see only small incremental changes in the context of the real impact AI is having on the business.

The popular belief is that the primary hurdle to successful AI and deep learning is data. The ability to gather sufficient negative and positive data sets to train the AI model to do the necessary task on its own and achieve high levels of success that warrants its use in the main stream business process. Businesses are asked to drive a separate AI budget to help their organisations “transition” into adopting this “transformational”, “game changing” technology.

While this is true, at oceans.ai we believe the fundamental problems lies in the limitation of most AI technologies to address the need for data gathering to be an embedded process to the business process. This enables businesses to build their AI knowledge base while not disrupting their business functions, and the costs of AI build up is inherent in the business process.

To give an example, in the Oil and Gas industry, inspections are mission critical operations. These are essential to the core business, and making sure that the business doesn’t suffer disruptions. In this industry, disruptions are extremely expensive, especially offshore operations which incur a further manifold cost increase on disruptions. With the pressures of oil prices on the industry, it becomes extremely challenging for the business to carve out an exclusive budget for an experimental initiative in AI.

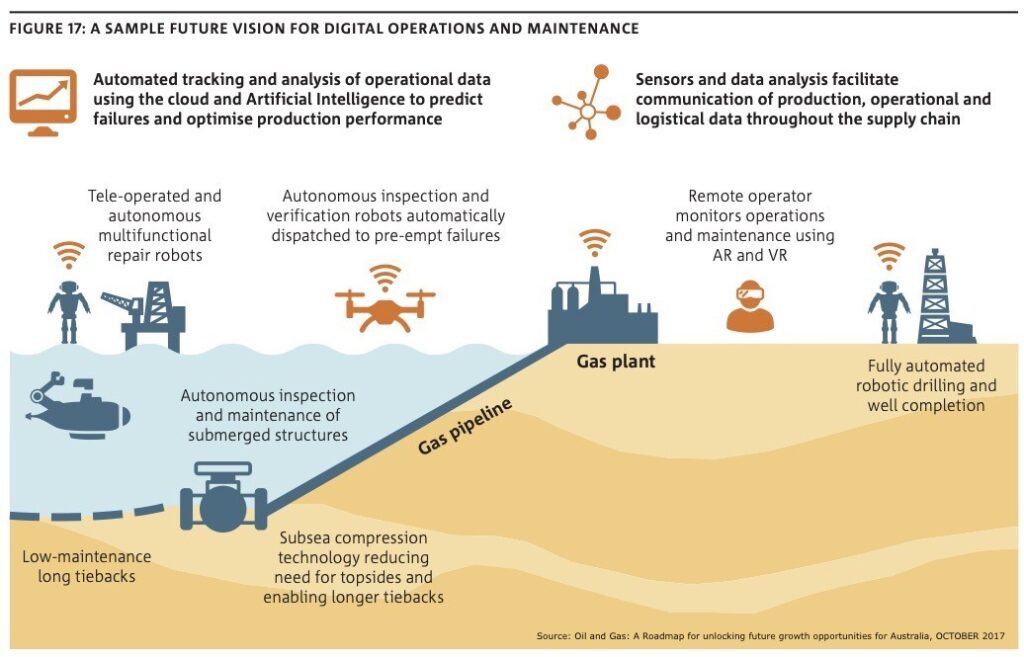

As per World Economic Forum (2017). Digital Transformation Initiative: Oil and Gas Industry, Geneva, it is estimated that, globally, digital transformation may create as much as $1 trillion in value for oil and gas firms, gained in part by transforming the way companies manage their assets and operations, and by enabling a more collaborative ecosystem for innovation and that autonomous inspections (with Robots and Drones) may help reduce inspection and maintenance costs by over 25%. The case for digital and robotic/autonomous efficiency is further enhanced by the fact that a significant portion of these industries have their operations in remote locations. All this while helping the industry and the world meet its global carbon emissions goals by bringing efficiency.

This is not just being seen in the Oil and gas market but across industries. With Covid-19, the impact on various business, their profitability and their need to keep a close watch on their work force safety, makes it imperative that the inspection industry finds ways in efficiency in their current business operations while building for more efficiencies in the future. as per a report by Global Newswire in April 2020 the Inspection, Repair, and Maintenance Market to Hit USD 60.26 Bn by 2027. Of this, Visual Inspection plays a key role and across locations (Offshore, Onshore), by application (Oil & Gas {Upstream, Midstream, Downstream}, Renewable {Solar, Wind, Hydro}, Power Generation, Manufacturing, Infrastructure, Marine, Aerospace & Defence, Automotive, Others).

The key aspect of inspection and maintenance is not if organisations need to make that spend but how will they find ways to reduce this cost while keeping their business and operations safe, persistent and sustainable.

This is where oceans.ai comes in. In partnership with Ocean Atlantic International, we have built DIVE, a platform that forms an integral part of your inspection business, while building up your knowledge base and data sets for successful AI implementation. This further linked to Deep DIVE will help your progression to autonomous inspections seamlessly and efficiently, while actually contributing direct and intrinsic value to your business operations.

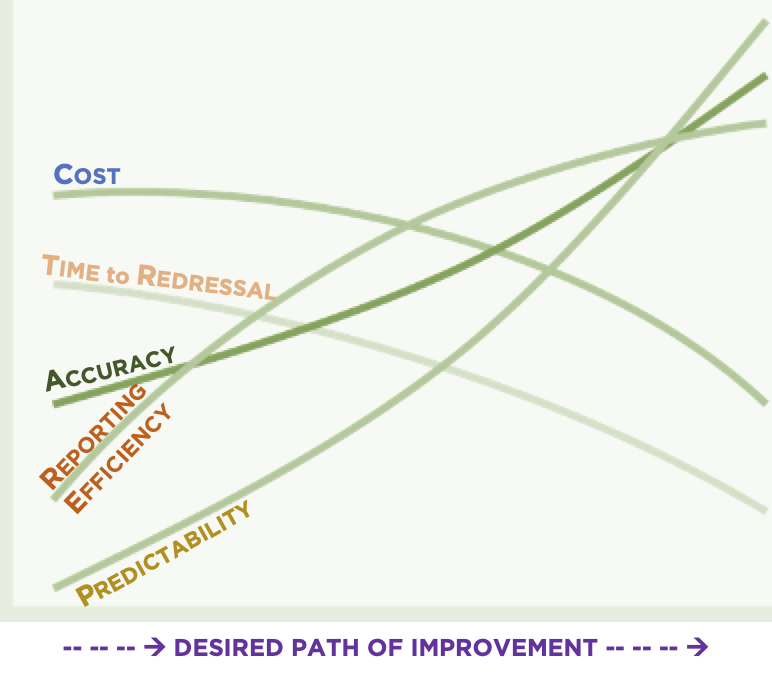

While delivering this intrinsic value, DIVE enables you to reduce your inspection logistics costs, time to reporting and time to redressal while improving your collaborative efficiency across global specialists and enabling you to cumulatively build up intelligence to improve accuracy and predictability. DIVE is designed by engineers for engineers.

Talk to us more at sales@oceansai.tech

Ref 1: https://www.globenewswire.com/news-release/2020/06/16/2048499/0/en/Inspection-Repair-and-Maintenance-Market-to-Hit-USD-60-26-Bn-by-2027-Surging-Demand-for-IRM-Services-across-Industry-Verticals-to-Boost-Market-Growth-Fortune-Business-Insights.html

Ref 2: World Economic Forum (n.d.). Robots and drones: automation on the rise,

Leave a reply