A(I) case in point: Offshore Inspection Services

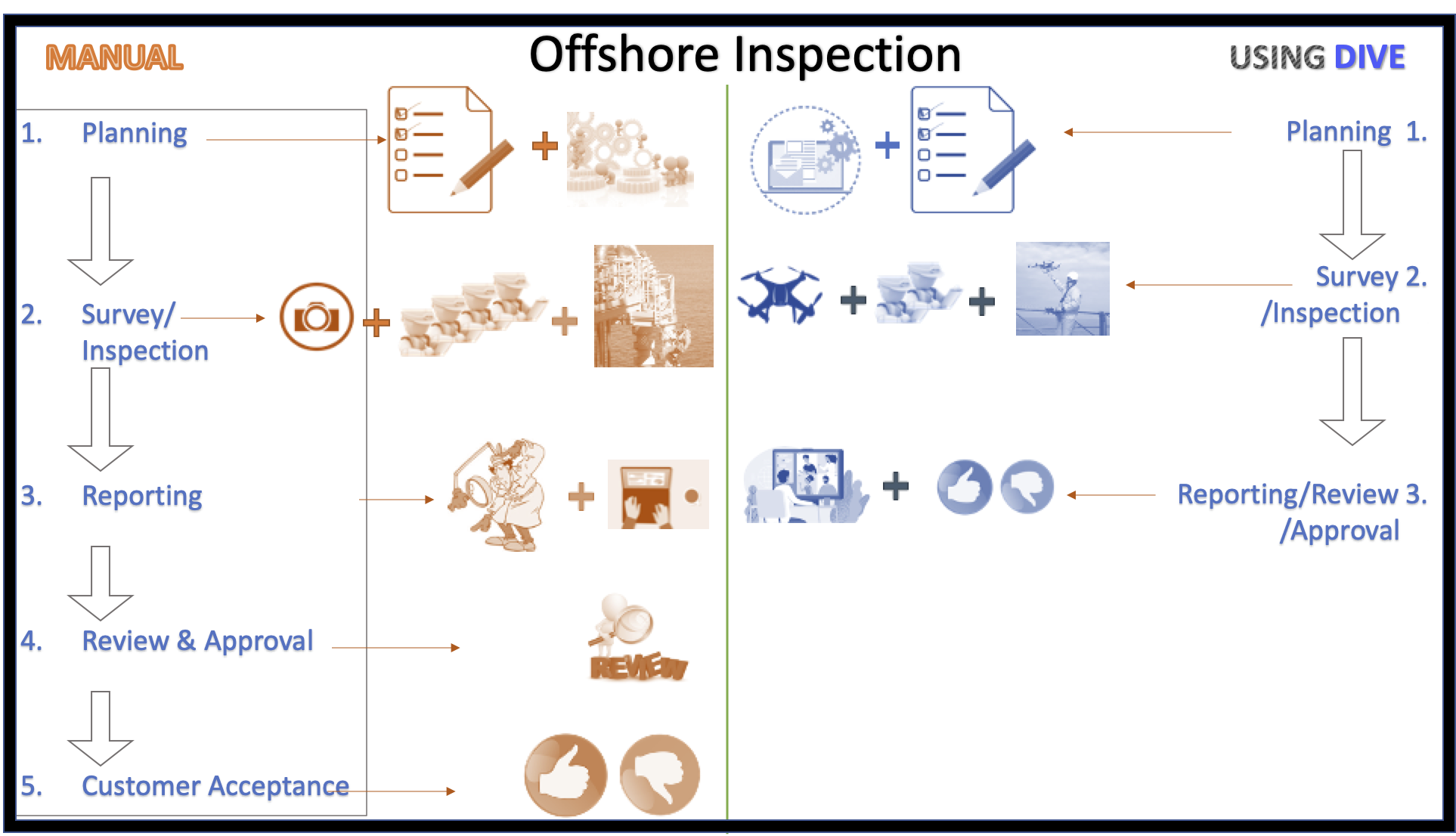

We now have a framework of how an AI strategy can be applied within a business framework. Needless to say, the proof of the recipe is in the output. Below, we elaborate the application of DIVE in a business process and are seeing demonstrable gains in business process efficiency: Offshore Inspection Services.

Context:

The business has been providing inspection and maintenance services for the Oil and Gas industry for a few years. The organization is driven by experts in the inspection business for many years, a sum-total of over 200+ man years of experience. The business has terabytes of historical data on inspections.

The Challenge:

Have been doing inspection projects for years now, have collected tons of inspection data and knowledge and information. Over the years their offshore inspection projects have stayed logistically complex, costly due to the following factors in the data capture part:

- the overall planning – manpower, schedule, mobilisation, international travel especially to remote locations

- skills required – the specialists required, the analysts required, the engineers required, the transportation

- preparation needed and uncertainties of weather and operations – the scheduling, the logistical operations, the approvals, weather clearances

- extended over large areas – many of the remote / offshore inspections extend over large tracts of area and manually spanning those areas takes time

- high risk and hazardous environments – the companies inspection environments are usually high risk and hazardous, the more the people placed there the higher the risk

After the data capture is done, the company’s post processing is a sequential process where:

- the processing of the inspection data using analysts and experts are time consuming, consumes days if not weeks to complete the analysis and report preparation.

- then there is a review done internally with corrections and alternations

- then the report is submitted to the customer for further review and change cycles, before it gets submitted

- then the customer takes action on the report findings.

The DIVE solution:

We deployed a DIVE instance for the business on the google cloud platform. DIVE is accessible from anywhere by their users from Africa, Europe, APAC and Australia. While their inspections teams are in remote locations with their drones/cameras for inspections, their specialists and analysts can be located anywhere in the world. As a result, their:

- Teams have become leaner and thus easier to mobilise and with reduced risk and cost

- Inspection have become more efficient, predictable and easier to plan

- The on-location skills required are more controlled and less costly

- Analysis and reporting have become collaborative process rather than a linear process thus sharply reducing the reporting time, down to a week from 2.5 – 3 weeks.

The business’ historical data is in parallel being processed on the platform. Enabling both a single repository of knowledge and training for the organisation, while building up the required data capacity which Deep DIVE is in the background processing for automated Inspections.

The outcome:

The business anticipates in a short time to be able to push in near-real-time, inspection data to the DIVE platform and be able to autonomously complete a significant portion of the inspection even before the data capture is completed. The business is also in parallel assessing an autonomous drone inspection platform, which post assessment can be integrated with DIVE/Deep DIVE and a near autonomous inspection platform will be deployed.

This is expected to deliver the business significant efficiency of costs, manpower and timelines while mitigating risks and significantly increasing accuracy and reliability of inspections.

The business is already seeing significant reduction in costs and improved profitability and efficiency. In the long term this is expected to increase and enable the business to scale and grow rapidly.

Footnote:

While we applied it to offshore oil and Gas, the key parameters of this applies to any remote location inspection service and activity. DIVE/Deep DIVE is flexible and scalable and we expect to see significant applications in the offshore and remote onshore energy and renewables industry.

To know more about our DIVE platform reach us at sales@oceansai.tech

Leave a reply